Automobile starter motor and automobile generator maintenance

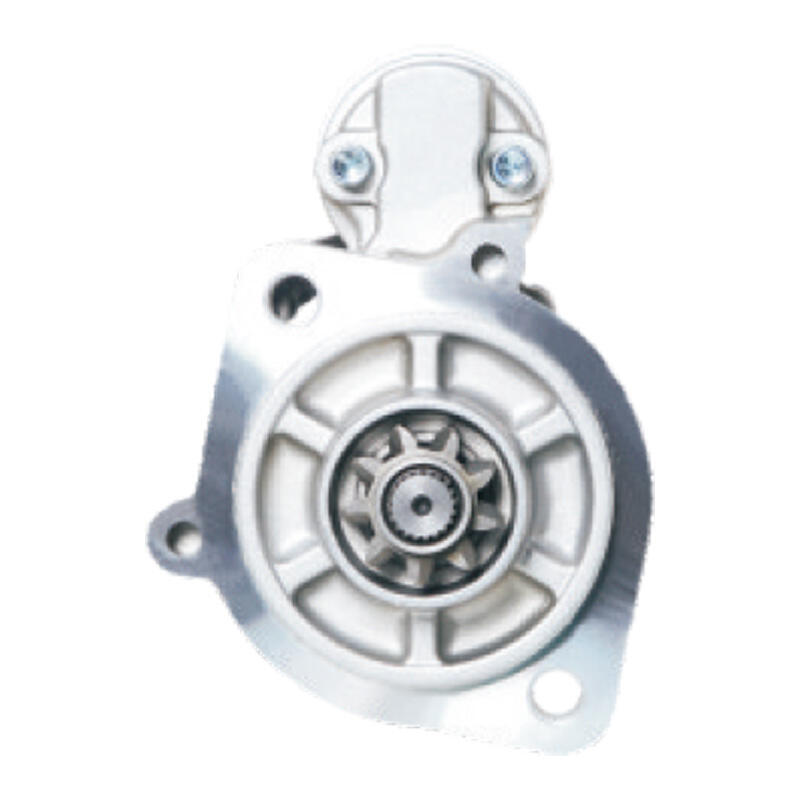

The role of the starter motor is to convert electrical energy into mechanical energy, which mainly includes three parts: electromagnetic switch, electronic motor, clutch. The motor is the key part of the car to start, if it goes wrong, the car can only stall; The generator serves as a power supply for storage batteries and electrical appliances. Here we look at the common faults of the starting motor and the generator, the causes of the faults and the methods of elimination.

When we drive a car, we usually turn the ignition key clockwise to start the starter motor. Do not run the starter motor for more than 5 seconds at a time. If the starter motor must be started more than once, first return the ignition key to the "I" or "O" position. In case the starting system is found to be faulty, it is necessary to check the car first, and do not remove the starting motor immediately. After it is confirmed that the starter motor is faulty and disassembled for maintenance, it is necessary to perform relevant tests on the experimental bench before re-installation.

Before checking the starting motor, check whether the battery is working properly, that is, check the voltage, electrolyte amount, and electrolyte specific gravity.

Through acoustic detection, the following faults can be identified, which are mainly caused by problems with the starter itself, the starter installation and the flywheel tooth ring of the engine: When the starter engages, the starter makes an abnormal noise, but the engine runs slowly or does not run; No meshing sound, starter meshing failure.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

IS

IS

UR

UR

BN

BN

MN

MN

NE

NE

TE

TE

KK

KK

KY

KY